Getting your contract as a consumer can be daunting when you’re not familiar with industry terms. It’s important to us that you have the tools to understand the scope of your contract before you sign it!

We could all use a study guide from time to time, so consider this your insider crash course!

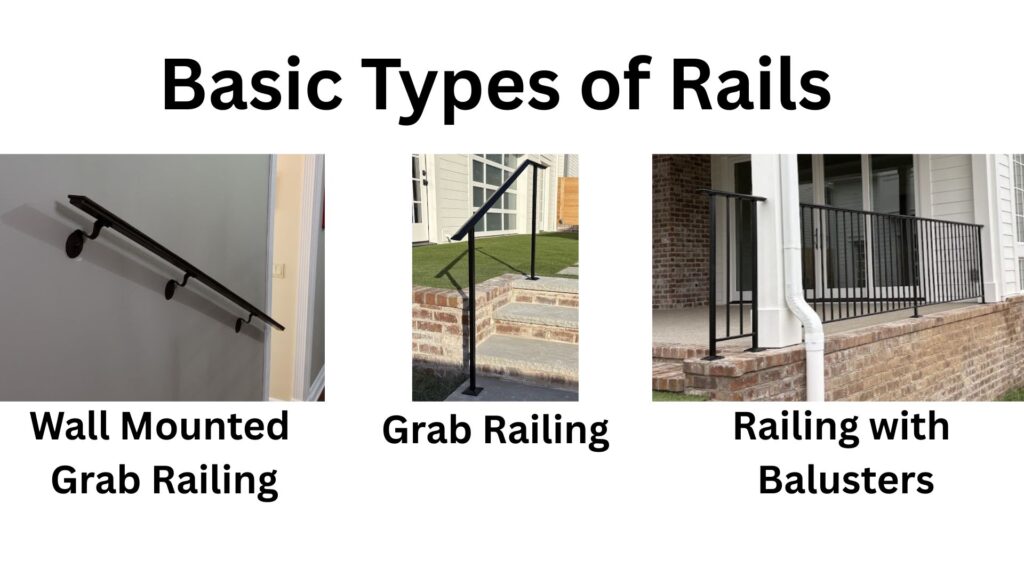

In this post we’ll go over definitions you may see in your contract, common types of rails, & installation methods.

Definitions:

Balusters: (often confused with pickets) The vertical or horizontal supportive material inside a railing frame.

Pickets: (often confused with balusters) The vertical or horizontal supportive material inside a fence frame.

Solid stock: is material that is not hollow. Solid stock is very sturdy and usually preferable over hollow stock for exterior projects.

Hollow stock: is material with a gap in the center. Depending on the gauge of material, it can be more or less durable. Hollow stock has it’s applications, but can expand/contract with the weather which leads to condensation on the inside of it, rust, and paint imperfections.

Molded cap rail: is the rounded material that gets welded on top of rail frames to give your hand a comfortable gripping point. We’ll talk about molded cap rail terminations in another post!

Cover shoes: are used to obscure the installation method. They help give the project a seamless finished look and come in many design options depending on your style preference! Cover shoes also protect the bottom of posts and fitment from water damage.

Most customer inquiries are for railings. They’re a very necessary safety measure for many people, but not everyone knows what kind of railing fits their project best.

Wall mounted grab railing’s are just what they sound like. They’re grab rails mounted into the wall with stand off brackets. Wall mounted grab rails are great for thinner stairwells that you don’t want to make smaller.

Grab railing is fabricated with two posts going to the ground. Many clients choose this option when their project doesn’t require a railing for codes, but they still want something to help with mobility.

Railings with balusters, often called railings, have material to infill the frame. Balusters can be vertical, horizontal, or any number of combinations. Balusters can even be substituted with ornamental elements such as castings. These railings are often required for codes and safety reasons.

Codes are different depending on municipality and building type, so if you have any questions just reach out!

Common Installation Methods

There are two primary modes of installation: Core drilling & mechanical fastening

Core drilling involves drilling into the brick, aggregate, or concrete to remove a cylinder of the material. The post is placed in the hole and a special cement is poured around the post. We use cover shoes to hide any aesthetic difference in material for a seamless appearance. Core drilling creates an extremely sturdy end result and helps prevent weathering so it’s primarily used on exterior projects.

Mechanical fastening involves using concrete anchors, screws, or bolts to install the project. This method can be used on several materials (wood, masonry, drywall, etc.) and produces less dust so it’s typically used on interior jobs. Mechanical fastening can be used for wall mounted grab rails as well as railings. When installing posts to the floor we utilize cover shoes. The cover shoe hides any visible fasteners for a seamless look and protects the base plate. When mechanically fastening exterior projects we add construction adhesive to prevent water intrusion.

If you’re wondering what the best installation method is for your circumstance, reach out to our team!